1997 to 2004 Corvette C5 Lowering Suspension Bolts - Long Rear Bolt Kit (8pc Set)

Brand : BDE Systems

- SKU:

- BDE-601

- Condition:

- New

Botello Dynamic Engineering (BDE) Systems LLC - Chevrolet Corvette C5, Rear Suspension Lowering Kit for 1997-2004 Corvettes - 8-piece Rear Kit. This kit works on all Corvette C5 models to include the coupe, convertible, FRC, STD, Z51 and Z06 models.

What's included with this sale:

- QTY (2) Grade 8 Bolts, DIN 931 Metric in a 7" length in Yellow Zinc Chromate Plating – Made in the USA.

- QTY (4) Grade 8 1.73” OD Oversized Washers, in Yellow Zinc Chromate Finish – Correctly oversized washers – Made in the USA.

- QTY (2) Grade 8 Steel Nyloc (Locking) Nuts with Flared Base, in Yellow Zinc Chromate Finish – Made in the USA.

- QTY (1) Install Instructions – Basic pamphlet guide including color images.

- QTY (1) Packing Slip

- QTY (1) USPS Priority Mail Shipping (2-3 Day Service) with tracking & insurance - USA customers only

***International Customers Pay $19.99USD for Export/Import, VAT Fees, International Customs Paperwork, Tracking and Delivery***

If you are reading this, then chances are you don't necessarily like the wheel gap presently in your C5 rear end. BDE-Systems has experience in lowering kits for Corvettes and due to the success of our long and best-selling C4 lowering kits and brake upgrade kits, we now offer a kit for C3 & C5 Corvettes. Shortly after purchasing our C5 Z06 Corvette we went to the shop and started looking for ways to improve on an already outstanding platform, the C5 Corvette. Short going to coil-overs, our C5 Corvette Lowering Kits are the best way to improve the look of your Corvette, increase responsiveness, provide long-lasting serviceability, while saving you some hard-earned money.

THIS LOWERING/RIDE HEIGHT PROVIDED BY THIS KIT IS ADJUSTABLE TO YOUR LIKING - our C5 Z06 is lowered to near max length. With the combination of rear Grade 8/Class 10.9 bolts, Grade 8/Class 10 non-marring nylock flange nuts, true oversized M14 washers (1.73" outside diameter - OD) and hardware in a matching yellow zinc finish (providing years of protection from the elements), we know this is the highest quality and performing C5 bolt lowering kit that any Corvette manufacturer or vendor carries. BDE-Systems LLC will only sell you the correct, OEM strength Metric Class 10.9/Grade 8 Hardware Required by General Motors Corp. Certs of Conformance and Lot Traceability records kept on site and are available for review.

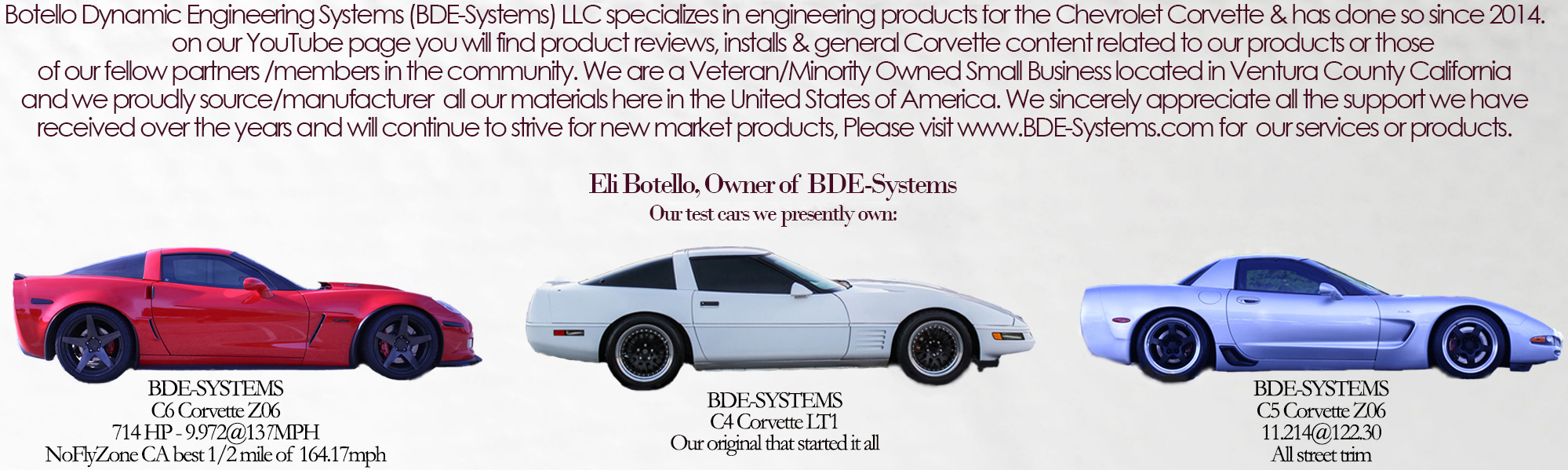

We develop, test and street/track run all our hardware on own BDE-Systems' Corvettes we are lucky to own:

- 1987 Corvette TPI - A cruiser and my first car, purchased with my enlistment bonus in 2001

- 1994 Corvette LT1 - high 12 sec car

- 2002 Corvette Z06 - low 11 sec car

- 2007 Corvette Z06 - high 9 sec car

Rest assured, we aren't a reseller looking for a cheap & quick dollar - We drive what we sell. We have been manufacturing and selling these kits on our secure website www.BDE-Systems.com, The CorvetteForum and eBay since 2014 - Thanks to the continued support, our kits are now available on our Amazon Pro Seller Store with PRIME shipping.

Size Matters

- Stock Bolt Length - 5.5" of useable length

- Common Aftermarket Lowering Bolt Length - 6.5"

- BDE-Systems LLC Lowering Bolt Length - 7.00" (inch) bolt length

Our ADJUSTABLE length results in an adjustable drop range from .1" to over 4" plus (dependent on suspension options, mileage, vehicle weight & general suspension condition, much like any coilover or suspension drop kit). Adjustment is done by simply threading the nut/bolt combination to the desired height.

Strength Matters

BDE-Systems Lowering Bolts have been meticulously engineered to adhere to the highest standards of quality and strength. Our bolts are classified as Grade 8/Metric Class 10.9, complying with the esteemed DIN 931 certification. Furthermore, it is essential to highlight that the entire hardware kit provided by BDE-Systems LLC also meets or surpasses the rigorous Grade 8 standards as outlined by ASTM A324 Grade BD and SAE J429. This guarantees the utmost level of quality, durability, and strength in the components. It is important to emphasize the significance of these designations, as it is not uncommon to find kits in the market that utilize Grade 5 hardware instead. Such a substitution of the original Grade 8 design not only bypasses the scrutiny of GM's Engineering Team but also poses a risk to both your vehicle and personal safety. These shortcuts are typically motivated by cost-saving measures, compromising the integrity and performance of the kit. Grade 8 bolts exhibit superior tensile and shear strength compared to Grade 5 bolts, with certified levels of over 21% higher in shear strength and 25% higher in fatigue/tensile failure levels. This advantage extends to metric bolts as well, specifically when comparing Class 8.8 to Class 10.9. The lower grade bolt, in both cases, reaches its maximum elongation and fracture point significantly earlier than the higher-grade bolt, which demonstrates its superior resistance to deformation.

Grade 5 hardware is characterized by its lower quality and is primarily intended for general applications, such as carpentry, household use, and low-stress domestic purposes. The absence of appropriate certificates of conformance or lot traceability for lower tensile strength hardware further emphasizes the disparity in quality. Conversely, Grade 8 hardware, like that employed by BDE-Systems, undergoes stringent testing, and conforms to specific standards, ensuring its suitability for demanding automotive applications. Grade 8 hardware stands as a superior choice compared to Grade 5 due to several significant factors that contribute to its enhanced strength and reliability. In the realm of fasteners and mechanical components, the grading system provides a standardized means of categorizing the tensile strength and overall quality of materials used. Here are the key reasons why Grade 8 hardware surpasses Grade 5:

- Tensile Strength: Grade 8 hardware exhibits a higher tensile strength compared to Grade 5. Tensile strength refers to the maximum load a fastener can bear before breaking. Grade 8 fasteners are engineered to withstand greater forces and loads, making them ideal for applications that demand high load-bearing capacities and structural integrity.

- Carbon Content: The disparity in tensile strength can be attributed to the higher carbon content in Grade 8 hardware. Carbon is a crucial element that enhances the strength and hardness of the material, enabling Grade 8 fasteners to withstand greater stress and deformation without compromising their integrity.

- Alloying Elements: In addition to carbon, Grade 8 hardware incorporates alloying elements such as chromium, molybdenum, and vanadium, among others. These elements further enhance the strength, hardness, and overall performance of the fasteners, providing them with superior resistance against deformation, shearing, and fatigue.

- Durability: The increased strength and robustness of Grade 8 hardware translates into improved durability. Grade 8 fasteners are designed to withstand harsh conditions, heavy vibrations, and extreme temperatures without compromising their structural integrity. This durability ensures long-term reliability and minimizes the risk of failure or damage.

- Safety and Reliability: The use of Grade 8 hardware ensures a higher level of safety and reliability in critical applications. By utilizing fasteners with superior strength and load-bearing capabilities, the risk of fastener failure, structural collapse, or mechanical breakdown is significantly reduced, enhancing overall operational safety and stability.

- Industry Standards: Grade 8 hardware adheres to strict industry standards and specifications, such as those outlined by organizations like the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE). These standards ensure consistent quality and performance, as well as compatibility with various industry applications and requirements.

In summary, Grade 8 hardware surpasses Grade 5 in terms of tensile strength, carbon content, alloying elements, durability, safety, and compliance with industry standards. The superior properties of Grade 8 fasteners make them the preferred choice for applications that demand robustness, reliability, and optimal performance under demanding conditions. By selecting Grade 8 hardware, engineers, manufacturers, and individuals can ensure the longevity, safety, and efficiency of their projects or equipment.

- Common Aftermarket Bolt Rating: Grade 5 or worse - It is important to note that a common rating for aftermarket bolts is often Grade 5 or even lower. When purchasing from a vendor who does not explicitly specify the Grade/Class Bolt, there is a high probability that substandard materials are being used. These inferior materials are typically obtained at lower costs locally or through online channels, and then resold to unsuspecting customers.

- BDE-Systems Bolt Rating: Grade 8/Class 10 - Our bolt grade matches the OEM GM factory bolt Grade 8 rating.

Since the 1950s, General Motors (GM) has been utilizing Class 10/Grade 8 bolts in the rear suspension of their automobiles and Corvettes. The selection of Class 10/Grade 8 bolts by GM reflects their confidence in the strength and reliability of these bolts for critical automotive applications. It is worth noting that all BDE-SYSTEMS LLC kits we offer maintain the same class/grade as the original equipment manufacturer (OEM) used by GM plants. By aligning with GM's choice of Class 10/Grade 8 bolts, BDE-SYSTEMS LLC ensures that their kits maintain the highest standards of quality and performance. This commitment to utilizing the same class/grade as the OEM highlights their dedication to delivering products that meet or exceed the specifications and requirements set by reputable automotive manufacturers.

Here is just a small sample size of CorvetteForum users that you can look up as they have had their lower GRADE 5 BOLTS FAIL - You don't need to purchase from us but please ENSURE you are getting GRADE 8 materials only:

- CorvetteForum Senior Member Greengear - failed lower grade bolts

- CorvetteForum Senior Member Kinkajou - failed lower grade bolts

- CorvetteForum Senior Member FR 73 454 - failed lower grade bolts

- CorvetteForum Senior Member Danbo - failed lower grade bolts

- CorvetteForum Senior Member C5Natie , he and I had our friend in LA total his C4 over a weaker rear bolt failing at highway speeds, fortunately accident was not fatal - failed lower grade bolts

Quality and Certification Matters

BDE-Systems LLC is an approved Amazon FBA Business Partner (2023). We maintain on-site Certificates of Conformance and Lot Traceability records for the materials utilized in our products. While we have done this for many years, our recent certification meant that our records underwent a thorough evaluation by Amazon.com LLC during the application process for our current Amazon FBA Business Account, resulting in successful approval. By diligently preserving Certificates of Conformance (CoC) and Lot Traceability records, we uphold a high standard of accountability and quality assurance. These records serve as tangible evidence of our commitment to meeting and exceeding industry requirements and regulations, and our commitment to you. The evaluation and approval of our records by Amazon.com LLC for our Amazon FBA Business Account further validates our adherence to stringent quality control measures. This endorsement from a reputable platform highlights our dedication to upholding the highest standards in our business operations.

When evaluating kits or components, it is crucial to prioritize transparency regarding the material, grade, and class of the hardware being utilized. Kits that fail to mention or provide details about the hardware used are highly likely to incorporate Grade 5 alternatives. By being vigilant and selecting kits that adhere to Grade 8 standards, you can safeguard the performance, reliability, and safety of your vehicle.

Our hardware finish exceeds OEM GM standards as our bolts, nuts and washers are treated to a yellow zinc chromate coating to protect your new kit from the natural elements for many years to come. Yellow zinc chromate is a chemical conversion coating that is applied over zinc plating during the surface coating process. Zinc plating is a soft, ductile, marginally solderable, corrosion-resistant finish. It protects the substrate and corrodes before the base metal, unlike most other commonly plated metals, thus protecting your new Grade 8 Steel parts.

With the combination of the rear Grade 8/Class 10.9 bolts, Grade 8 non-marring flanged nyloc nuts, Grade 8 oversized washers (hardware in a matching yellow zinc chromate, providing years of protection from the elements) and Hyperflex Polyurethane low profile bushings, this is the best quality and performance C4 bolt lowering kit that any Corvette manufacturer or vendor carries.

Adjustability Matters

FRONT: We carry BDE-Systems C5 Front Lowering Bolts (other ads) that have a lower profile spring pad cushion, so they allow for your C5 Corvette to be lowered well past the point of simply using your OEM bolts to lower your Corvette front - See our other add for complete FRONT AND REAR kits.

REAR: BDE-Systems C5 Rear 7" Lowering Bolts provide an increase of 1.5" in overall length when compared to the OEM bolts, this allows for an extended threaded rod portion to be used for compressing/decompressing of the C5 suspension, which provides the MAXIMUM range of ride height adjustment (well past simply dropping your C5 using the OEM bolts). We found that the common 6.5" bolt length would leave some adjustment room on the table and often left the nut at the end of the bolt threads. We tried a 8" bolt and while it worked, it’s not a length we recommend on certain models as select aftermarket wheels may change the wheel offset/height/width and in turn, alter the general suspension geometry and spacing in relation to the bolts/suspension components vs the wheel/tire, possibly causing interference or a tire puncture. We found the 7" bolt to be an excellent compromise in both areas, lowering/adjustable range and maintained a safe distance from potential interference with the rim and tire, even with aftermarket wheels. WE ALSO STOCK AN 8" BOLTS THAT WE CAN SWAP IN AT NO COST, PLEASE EMAIL US FOR THIS OPTION.

The Advantages of Lowered/Adjustable Suspension

In general, having the vehicle lower to the ground can increase the grip of the tires on the roadway by reducing the suspension travel to have body weight and momentum shifted to the rear wheels. Additional stiffness can be desired in a suspension, and this is one of the perks that some drivers mention after lowering their suspension.

Body roll reduced

When the center of gravity has lowered one generally reduces body roll which in turn increases the responsiveness of the car. Corvettes aren't known rollover adverse vehicles but if there was a threshold or propensity of it, it would be reduced by lowering it.

Stock wheels and body spacing

This may not be news to you C2 and C3 Corvette owners out there, but the suspension and ride height varies from Corvette to Corvette. Reports vary on stock height, but we've seen heights from about 26" to about 30", and we attribute this to suspension condition, year & model variances in suspension options and miles on suspension. This kit is an excellent way to remedy those variances and stabilize the rear end.

Aftermarket wheels and body spacing

When moving into the aftermarket wheel world it is often a necessity to lower the ride height of one’s vehicle to close the wheel gap and achieve that perfect stance. Our C5Z has 19" Fikse wheels for the street and 18" CCWs for the track, so the kit allows us to match the wheels to the ride height very easily – This will apply to your Corvette as well, the adjustability will work with your wheel and tire setup.

Better aerodynamics

With a lowered suspension, there's less air going underneath the vehicle, and this can create a better outcome for wind drag on a car. GM did design the vehicle with a rake for stability at high speed so keep at rake if that's your intended range - adjusting and monitoring the height at speed in conjunction with adjustments is recommended. The speeds we are talking about are off-road speeds not seen on commercial/commuter/highway roads. In other words, adjusting your height is fine for regular street and highway use without need to worry but if you drive in the 130+MPH range for sustained periods of time then monitoring/adjustments are recommended, just like any other lowering.

ATTENTION - WARNING

Shipping

FREE USPS Priority Shipping & Tracking is included to The United States with the sale price unless otherwise noted.

***WORLDWIDE SHIPPING *** We can ship to virtually any address in the world and are glad to serve our Corvette Customers overseas. The free shipping applies only to Continental US customers, but we do have a global business shipping account and all other locations only pay a flat rate of $19.99 as the International Shipping Rate. This includes customs paperwork, export/import and VAT fees.

Items will be shipped within 1 business day after receiving a clear payment, same day shipping is carried out when/where possible.

Returns Policy

We accept returns although we rarely see them; however, if there is ever an issue or concern, we are always willing to work it out if you contact us immediately. We will always strive to reach an amicable agreement upon any reports of concerns. You may also return an item if we shipped the incorrect item to you (wrong color or incorrect item) - at which point we will refund the new, unused item cost within 14 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received the wrong color or incorrect item, etc.). You should expect to receive your refund within three weeks of giving your package to the return shipper, however, in many cases you will receive a refund within a faster time frame, that is a worst case/special circumstance scenario. This period includes the transit time for us to receive your return from the shipper (3 to 7 business days), the time it takes us to process your return once we receive it (2 to 4 business days), and the time it takes the bank system to process our refund request (1 to 2 business days). We strive to ensure your satisfaction and our customer support line is there to walk you through the installation, answer technical questions and offer advice on installation methods. If you need to return an item, please Contact Us with your order number and details about the product you would like to return. We will respond quickly with instructions for how to return items from your order.

Thank you for taking the time to visit us here at Botello Dynamic Engineering (BDE) Systems LLC. We were founded in 2014 with the intention of bringing the Corvette market a breath of fresh air with new products. We’re an LLC based out of Ventura County California and all our materials for our products are sourced in the United States. BDE-Systems is a minority owned, disabled US NAVY Veteran with all our eBay sales generating a percentage of charitable contributions to The NAVY SEALS FUND at https://navysealsfund.org/ Thanks to the response in the C4 Corvette market over the last few years, we have been able to expand into the C2, C3, C5, C6 and C7 market Corvette market - Due to all the continued and consistent sales/community support, we purchased a C5 Z06 and a C6 Z06 Corvette. These vehicles are not just enjoyed by us daily, they have served as "test mules" and allowed us to release/research additional products or services in this field; thankfully, we also gained new partnerships in the Corvette and Automotive Industry in doing so.

Thank you,

Eli Botello

Owner of BDE-Systems LLC

-

The rear lowering bolts came quickly and were easy to install. The rear of the car can now be lowered over an inch from what the stock bolts allowed.

BDE Systems is a great company. Good quality products at a very reasonable price.